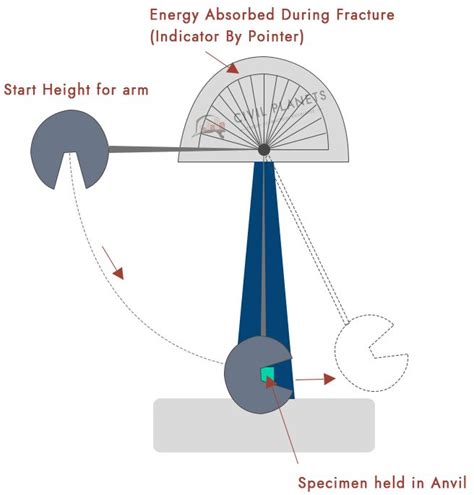

charpy impact test for foam|what is the charpy test : agency The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

ANNA (@annapep3) su TikTok |42.3M Mi piace.1.8M Follower.20 ♌️.Guarda l'ultimo video di ANNA (@annapep3).

{plog:ftitle_list}

10. 11. 12. Next. 360p. Coroa safadinha. 2 min Carlos5043675 - 360p. milf - coroa vadia da bunda grande fodendo blog amador com. 4 min Drummerpower - 360p. novinha da .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a .

The Charpy impact test provides characteristic values for the impact strength at high strain rates in the form of a surface area related value. The test measures the impact energy in relation to the fracture surface in joules.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures!The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

Impact test machine (A) Charpy impact test result analysis This testing was done according to ASTM A370, ISO 148, or EN 10045-1 standard without notched, the sample is placed in a horizontal position, ball pin hammer striking at the point of the notch but in the opposite direction.

what is the charpy test

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .measuring impact energy are: Charpy Test and Izod Test.Charpy impact test is a low-cost and reliable test method, which is commonly required by the construction codes for fracture critical structures such as bridges and pressure vessels. Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of .Srivastava analyzed the impact behaviors of sandwiches with a polyurethane foam core and E-glass fiber face sheets with the Charpy impact test, the Izod impact test, and the weight drop test [27]. However, the research objects of these works are usually a sandwich structure with a pure foam core; different core materials are not considered.To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

Download Table | Charpy impact test results for 6061 aluminum alloy quenched in different media from publication: Investigation of the Quenching Properties of Selected Media on 6061 Aluminum Alloy .

Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, test pieces, and testing machines used.

The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which .

foam testing results

foam testing images

charpy v notch impact test

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.

Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type (b)To determine the variation of impact strength of a material with change in temperature Experimental Method:

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. This research employs the Taguchi method and analysis of variance (ANOVA) to investigate, analyze, and optimize the impact strength of tough polylactic acid (PLA) material produced through fused deposition . Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

Charpy and Izod impact testing are two types of testing that mostly used by the industry as it was known as an economical quality control method. . polyurethane foam, and phenolic formaldehyde . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .Question: You were determining the Charpy impact strength for Your polyethylene material. You used hammer with 5J energy and standard impact test specimen (see slide 23) with notch (notch depth 1,2 mm). 64 % of the hammer energy was consumed for breaking the sample; what was the impact toughness of Your PE-material?

Ball Rebound Tester is a device designed to test resilience of materials such as foam, polyurethane and other similar materials. The unit comes certified in accordance with DIN EN ISO 8307 and ASTM D3574 industry standards. . EN10045 regulates the Charpy impact testing method, a widely used technique for assessing materials' toughness and .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

volumetric vs coulometric karl fischer titration supplier

Srivastava analyzed the impact behaviors of sandwiches with a polyurethane foam core and E-glass fiber face sheets with the Charpy impact test, the Izod impact test, and the weight drop test . However, the research objects of these works are usually a sandwich structure with a pure foam core; different core materials are not considered.

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force sensors on the striker's edge, allowing scientists to record the .4.3 The Charpy V-notch impact test in relation to other tests. 4.4 Factors influencing impact properties. 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces.Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material. History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

water standard 1 standard for volumetric karl fischer titration supplier

15 de out. de 2023 · Statistics. Favorites. Posts filter. GL. 15 Oct 2023, 21:12. 19.2k 0 38 65. GL. 15 Oct 2023, 21:12. 12.8k 0 9 4.

charpy impact test for foam|what is the charpy test